Enzyme Activity Calculator

Calculate enzyme activity and kinetics including reaction rates and substrate concentrations

Enzyme Activity

μmol/min (Units)

Specific Activity

U/mg (μmol/min/mg)

Reaction Rate

μmol/min

Calculation Details

Understanding Enzyme Activity

Enzyme activity is a measure of the catalytic ability of an enzyme to convert substrate into product. It is typically expressed as the amount of product formed (or substrate consumed) per unit time under specific conditions. The International Unit (U) of enzyme activity is defined as the amount of enzyme that catalyzes the conversion of 1 micromole (μmol) of substrate per minute under standard conditions. Specific activity (U/mg) represents enzyme activity per milligram of protein, providing a measure of enzyme purity and concentration. Understanding enzyme activity is crucial in biochemistry, molecular biology, clinical diagnostics, and biotechnology applications.

Key Parameters

Enzyme Activity (U)

The rate at which an enzyme catalyzes a reaction, measured in Units (U) where 1 U = 1 μmol of substrate converted per minute. This is calculated from the change in substrate or product concentration over time, accounting for sample volume and dilution factors. Enzyme activity depends on temperature, pH, substrate concentration, and the presence of inhibitors or activators.

Specific Activity (U/mg)

The enzyme activity per milligram of total protein in the sample. This parameter indicates enzyme purity—higher specific activity means more pure enzyme. During enzyme purification, specific activity increases as contaminating proteins are removed. In this calculator, specific activity equals enzyme activity as it assumes a normalized protein concentration.

Reaction Rate (μmol/min)

The velocity at which the enzymatic reaction proceeds, calculated from the change in concentration (ΔC) multiplied by sample volume and dilution factor, divided by reaction time. This represents the actual rate of substrate conversion or product formation in your specific experimental conditions.

Calculation Formulas

Enzyme Activity Formula

Where:

- ΔC = Change in concentration (Initial - Final) in μM

- V = Sample volume in mL

- D = Dilution factor (dimensionless)

- t = Reaction time in minutes

Example Calculation

Given:

- Initial concentration: 100 μM

- Final concentration: 50 μM

- Reaction time: 1 min

- Sample volume: 1 mL

- Dilution factor: 1

Calculation:

ΔC = 100 - 50 = 50 μM

Enzyme Activity = (50 × 1 × 1) / 1 = 50 U

Applications of Enzyme Activity Measurements

Research & Development

- • Enzyme characterization and optimization

- • Studying enzyme kinetics and mechanisms

- • Drug discovery and inhibitor screening

- • Protein engineering and mutagenesis studies

- • Metabolic pathway analysis

Clinical Diagnostics

- • Liver function tests (ALT, AST, ALP)

- • Cardiac markers (CK, LDH, troponin)

- • Pancreatic function (amylase, lipase)

- • Metabolic disorder screening

- • Disease diagnosis and monitoring

Industrial Biotechnology

- • Enzyme production quality control

- • Biocatalyst optimization for manufacturing

- • Food processing enzyme monitoring

- • Detergent enzyme characterization

- • Biofuel production processes

Quality Control

- • Enzyme preparation standardization

- • Lot-to-lot consistency verification

- • Stability testing during storage

- • Purification process monitoring

- • Product release criteria validation

Factors Affecting Enzyme Activity

Temperature

Enzyme activity increases with temperature up to an optimal point (typically 37°C for human enzymes), then decreases due to denaturation. Temperature affects reaction kinetics following the Arrhenius equation. Most enzymes lose activity above 50-60°C. Psychrophilic enzymes work best at cold temperatures, while thermophilic enzymes remain active at high temperatures.

pH

Each enzyme has an optimal pH where activity is maximal. pH affects ionization of amino acid residues in the active site, altering substrate binding and catalysis. Pepsin works best at pH 2 (stomach), trypsin at pH 8 (intestine). Significant pH deviations can cause irreversible denaturation. Buffer selection is critical for maintaining consistent pH during assays.

Substrate Concentration

At low substrate concentrations, reaction rate increases linearly with substrate (first-order kinetics). At high concentrations, the enzyme becomes saturated and velocity reaches maximum (Vmax, zero-order kinetics). The Michaelis-Menten equation describes this relationship. Km (Michaelis constant) is the substrate concentration at half-maximal velocity, indicating enzyme-substrate affinity.

Inhibitors and Activators

Competitive inhibitors compete with substrate for active site binding (increased Km, unchanged Vmax). Non-competitive inhibitors bind elsewhere, reducing Vmax without affecting Km. Uncompetitive inhibitors bind only to enzyme-substrate complex. Activators enhance enzyme activity through allosteric regulation or cofactor provision. Heavy metals, organic solvents, and some ions can inhibit enzymes.

Enzyme Concentration

At constant substrate excess, reaction rate is directly proportional to enzyme concentration. This linear relationship is essential for quantitative enzyme assays. Dilution factors must be accurately applied. Protein aggregation, adsorption to surfaces, or presence of enzyme inhibitors in crude extracts can cause deviations from linearity.

Cofactors and Coenzymes

Many enzymes require non-protein cofactors: metal ions (Mg²⁺, Zn²⁺, Fe²⁺) or organic coenzymes (NAD⁺, FAD, Coenzyme A). Holoenzyme (enzyme + cofactor) is catalytically active; apoenzyme (without cofactor) is inactive. Cofactor availability can be rate-limiting. EDTA chelates metal ions, inhibiting metalloenzymes. Some enzymes require specific ionic strength for optimal activity.

Best Practices for Enzyme Assays

- Use appropriate buffers: Maintain constant pH throughout the reaction. Select buffers that don't interfere with the assay or inhibit the enzyme.

- Control temperature: Use a water bath or temperature-controlled spectrophotometer. Pre-warm reagents to assay temperature.

- Ensure linearity: Measure initial rates where product formation is linear with time. Keep substrate depletion below 10-20%.

- Optimize substrate concentration: Use saturating substrate levels (typically 10× Km) for Vmax measurements or varied concentrations for kinetic studies.

- Include controls: Run blanks without enzyme, negative controls with denatured enzyme, and positive controls with known enzyme activity.

- Replicate measurements: Perform assays in triplicate or more to assess reproducibility and calculate statistical significance.

- Account for background: Measure and subtract non-enzymatic reaction rates and instrument background signals.

- Validate assay conditions: Confirm that activity is proportional to enzyme amount and time within the assay range.

- Document carefully: Record all assay conditions: temperature, pH, buffer composition, substrate concentration, time points.

- Store enzymes properly: Follow storage recommendations (temperature, glycerol, stabilizers). Avoid repeated freeze-thaw cycles.

References

The enzyme activity calculations and information are based on established biochemistry principles from reputable sources:

Note: This calculator provides theoretical enzyme activity calculations based on the input parameters. Actual enzyme activity measurements require careful experimental design, appropriate controls, and validation. Results depend on assay conditions including temperature, pH, buffer composition, substrate quality, and detection method. Always follow standardized protocols for your specific enzyme and application. For clinical or diagnostic purposes, use validated assays with appropriate quality control measures. This tool is for educational and research planning purposes.

Recommended Calculator

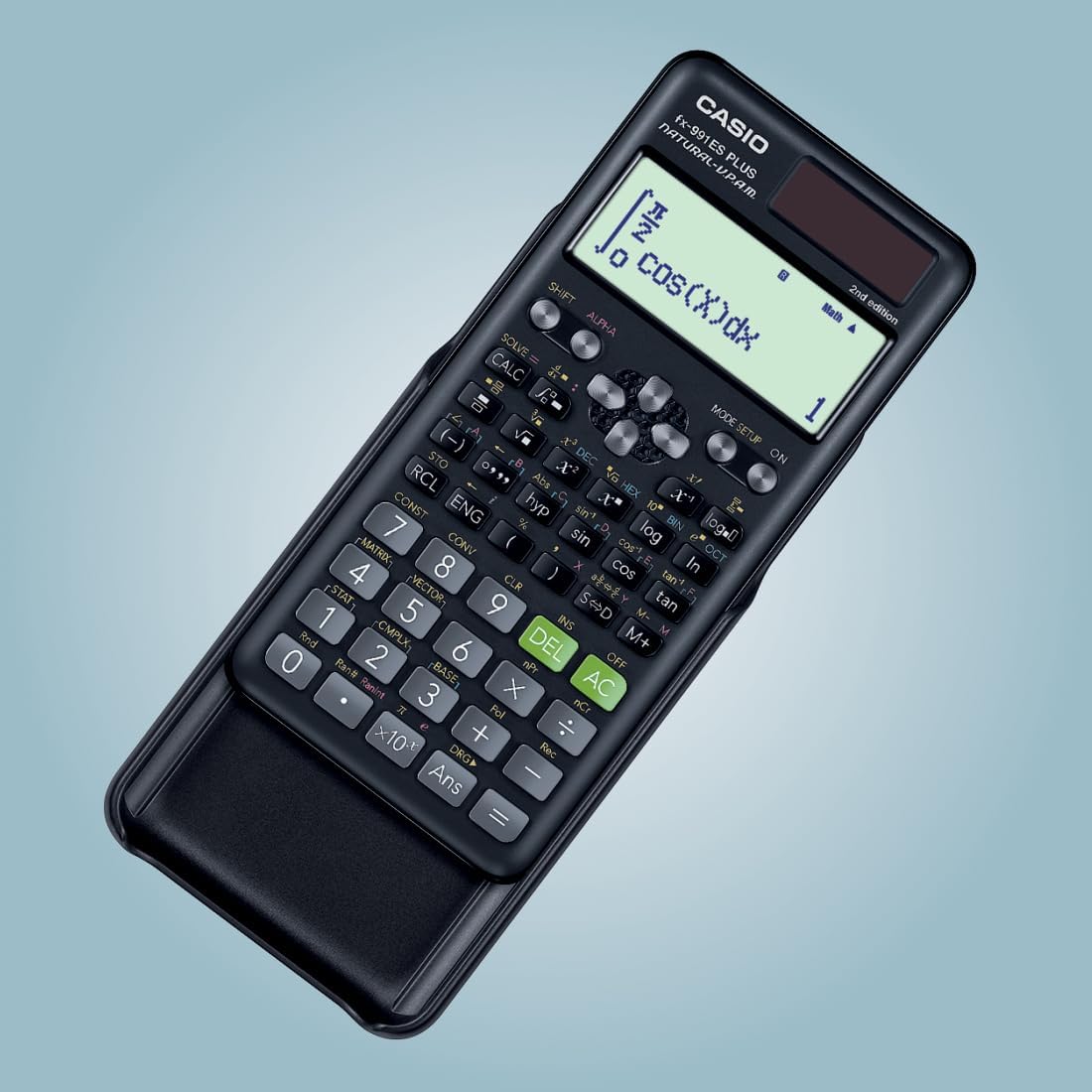

Casio FX-991ES Plus

The professional-grade scientific calculator with 417 functions, natural display, and solar power. Perfect for students and professionals.

View on Amazon