Wind Turbine Profit Calculator

Calculate potential profit, ROI, and payback period from wind turbine installations. Input your costs, turbine specifications, and electricity prices to estimate your wind energy investment returns.

Costs

Performance

Financial Parameters

Results

Annual Energy Production

Annual Revenue

Total Investment

Annual Profit

Total Profit (20 years)

Return on Investment (ROI)

Payback Period

Understanding Wind Turbine Economics

Wind turbines convert kinetic energy from wind into electrical energy. The economic viability of a wind turbine depends on multiple factors including turbine size, wind speed at the location, electricity prices, installation costs, and maintenance requirements. Modern wind turbines are designed to operate for 20-25 years with proper maintenance. The capacity factor (efficiency factor) typically ranges from 25% to 40% depending on the location's wind resources and turbine technology. This calculator helps you estimate the financial returns on wind energy investments.

Key Factors Affecting Profitability

- Wind Speed: Higher average wind speeds result in greater energy production and revenue

- Turbine Size: Larger turbines have higher initial costs but generate more power

- Location: Wind resources vary significantly by geography, affecting capacity factor

- Electricity Prices: Higher rates increase revenue and improve ROI

- Installation Costs: Site preparation, grid connection, and permitting affect upfront investment

- Maintenance: Regular maintenance ensures optimal performance and extends turbine life

- Government Incentives: Tax credits and subsidies can significantly improve economics

Types of Wind Turbines

Small Wind Turbines

Power: 1-100 kW

- • Residential and small business applications

- • Lower initial investment ($3,000-$150,000)

- • Can be installed on properties with adequate wind

- • Simpler permitting process

- • Typically 20-30 year lifespan

- • May qualify for residential incentives

Utility-Scale Turbines

Power: 1-5+ MW

- • Commercial wind farms

- • High initial investment ($1.3-$2.2 million per MW)

- • Greater efficiency and economies of scale

- • Complex permitting and environmental reviews

- • 20-25 year design life

- • Access to production tax credits (PTC)

Horizontal Axis (HAWT)

- • Most common design (90%+ of market)

- • Propeller-style blades on horizontal shaft

- • Higher efficiency (35-45% capacity factor)

- • Requires yaw mechanism to face wind

- • Better for high wind speed locations

- • Proven technology with extensive data

Vertical Axis (VAWT)

- • Alternative design with vertical shaft

- • Works with wind from any direction

- • Lower efficiency (15-25% capacity factor)

- • Simpler maintenance (generator at ground level)

- • Better for turbulent wind conditions

- • Less common, fewer proven models

Typical Cost Breakdown

Tower, rotor, nacelle, blades, generator, control systems

Site preparation, foundation, crane rental, labor, grid connection

Environmental assessments, permits, wind resource studies, legal fees

Inspections, repairs, component replacement, insurance, monitoring

Important Considerations

Wind Resource Assessment

Conduct a thorough wind resource assessment before investing. Wind speed measurements should be taken at hub height for at least one year to account for seasonal variations. Even small differences in average wind speed significantly impact energy production and profitability.

Incentives and Tax Credits

Federal Investment Tax Credit (ITC) and Production Tax Credit (PTC) can significantly improve project economics. State and local incentives, net metering policies, and renewable energy credits (RECs) may also apply. Consult with tax professionals to understand available benefits.

Grid Connection

Connecting to the electrical grid requires utility approval and may involve significant costs for transformers and transmission infrastructure. Net metering agreements allow you to sell excess power back to the grid. Check local regulations and utility policies before proceeding.

Note: This calculator provides estimates based on simplified assumptions. Actual results will vary based on specific site conditions, wind resources, turbine performance, local electricity rates, maintenance costs, and available incentives. The efficiency factor (capacity factor) represents the percentage of time the turbine operates at rated power - typical values range from 25-40% depending on location and turbine design. For accurate project evaluation, consult with wind energy professionals, conduct comprehensive wind resource assessments, and obtain detailed cost estimates from turbine manufacturers and installers.

Recommended Calculator

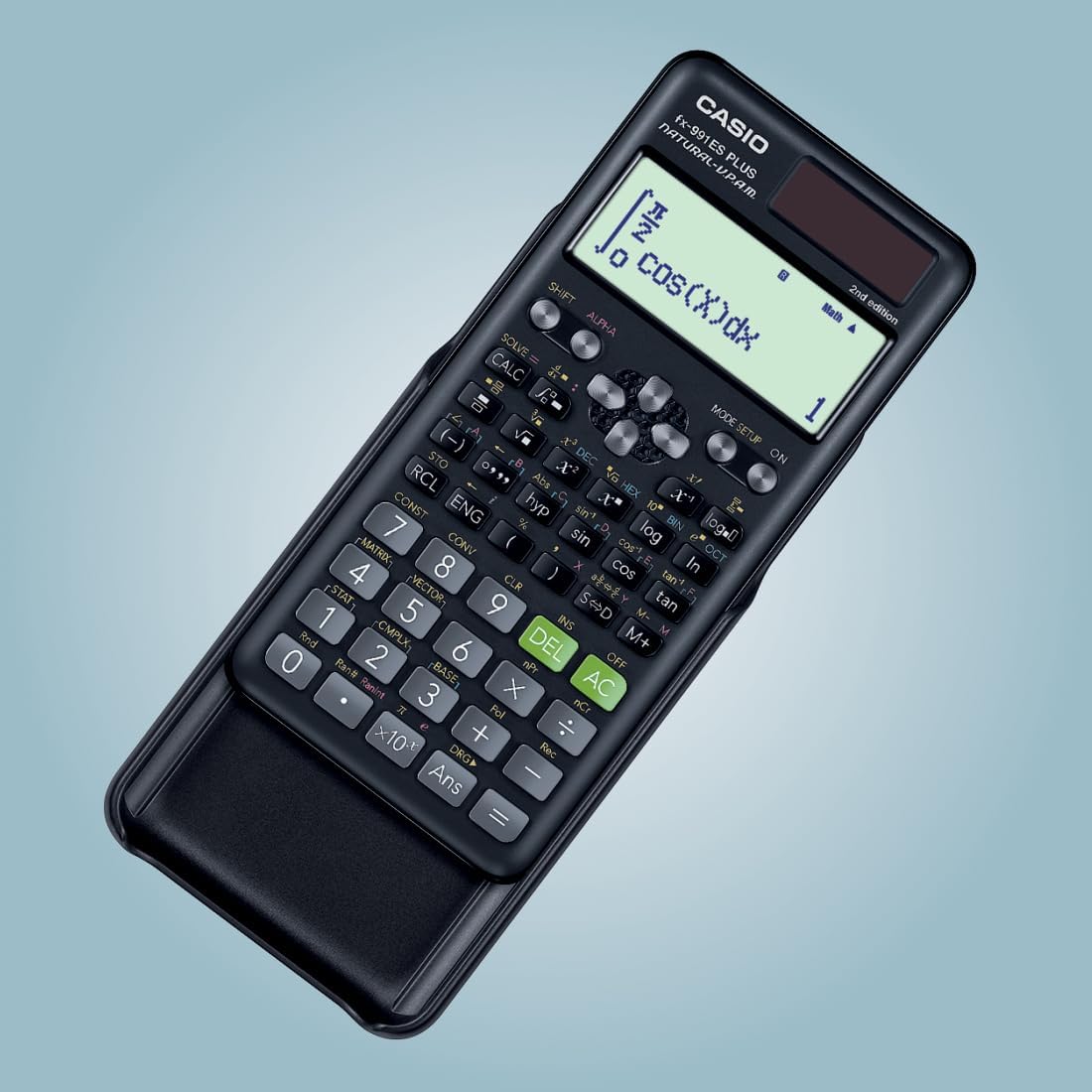

Casio FX-991ES Plus

The professional-grade scientific calculator with 417 functions, natural display, and solar power. Perfect for students and professionals.

View on Amazon